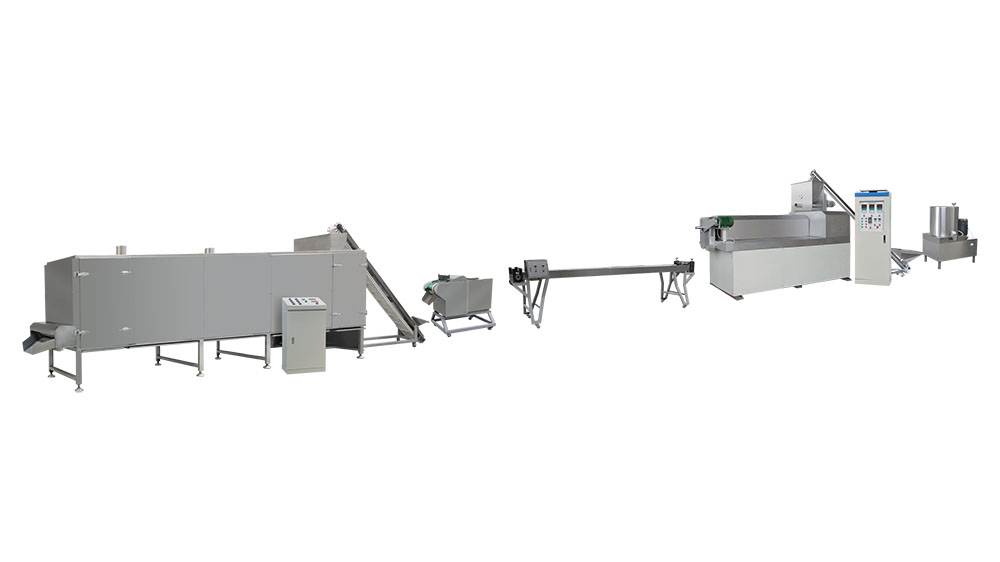

Pet chew production line

Production line description:

The pet chew production line is specially used for the production of dog chew products, which are extruded by a single screw extruder. The production line can produce pet chews in strip, rod, twist, two-color and multi-color shapes. During the chewing process of the pet, massage the teeth of the pet moderately, and at the same time promote the saliva secretion of the pet, and help improve its digestive function. Made of natural food, wear-resistant, non-toxic and harmless. Grind teeth and supplement nutrition.

Process composition:

1. Mixing machine: Add a certain proportion of water to the raw materials and mix them evenly.

2. Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Single-screw extruder: Under the conditions of high temperature and high pressure environment and screw extrusion, the die can be changed by adjusting the different feeds in the production department of the process, and the specific particle size and shape.

4. Cooling conveying: traction cooling conveying.

5. Cutting machine: Cut the chew into different sizes according to requirements.

4. Conveyor: convey the chew to the oven,

5. Multi-layer oven: The oven is mostly electric oven. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh bag, which reduces the moisture of feed particles, promotes the maturation rate and increases the shelf life.

6. Packaging machine: manual sealing machine and automatic packaging machine can be used.

Hotline:18763911927

Hotline:18763911927

Email:sales@renoextrusion.com

Email:sales@renoextrusion.com