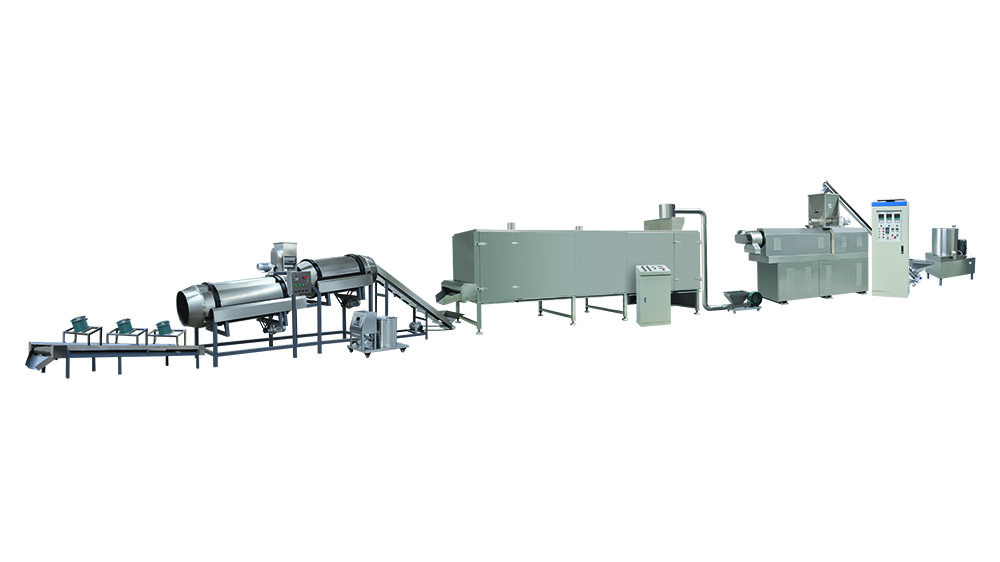

Pet food production line

Production line description:

Linao Machinery's pet food processing equipment uses twin-screw extrusion technology to produce dog food, cat food, dog chews, ornamental fish feed and other pet foods. It is a process that integrates mixing, conveying, shearing and kneading, steaming, cooking, sterilization, and molding. method. Extrusion technology can decompose protein, easy to digest and absorb, improve the nutrition absorption rate of pet food, and eliminate flatulence. Extrusion technology can gelatinize starch and produce a unique coke flavor, which can increase pet appetite. Therefore, extrusion technology produces Pet food is a premium pet food.

Process composition:

1. Crushing equipment: crush the raw materials to be crushed into powder according to actual needs.

2. Mixer: Mix the raw materials required for dog food production according to the formula. Different types of mixers can be selected according to the output of the production line.

3. Feeding machine: spiral or bucket conveying materials to ensure convenient and quick feeding and reduce secondary pollution from manual contact. Spiral or bucket conveying is selected according to the output.

3. Twin-screw extruder: Changdong Company has different types of extruder to choose from according to the output of the production line. The output ranges from 100kg/h to 5000kg/h. The specific product shape can be changed by changing the mold.

4. Air conveyor: convey the dog food to the dryer. The height of the air conveyor is determined according to the oven, and a hoist can also be used.

5. Multi-layer belt dryer: The dryer is divided into electric oven, oil (steam) oven, steam oven, etc., which can be selected according to the output and fuel convenience. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh belt. The drying time is adjusted by frequency conversion speed. There are three-layer, five-layer, and seven-layer stainless steel dryers of different models.

6. Cooling conveyor: cool the material and transport it to the next process.

7. Silo: store materials and wait for later spraying.

8. Seasoning line: There are manual octagonal cylinders, shotcreting and cylinders, lifting single drum, double drum seasoning lines, which are configured according to the output and the nature of the product.

Hotline:18763911927

Hotline:18763911927

Email:sales@renoextrusion.com

Email:sales@renoextrusion.com