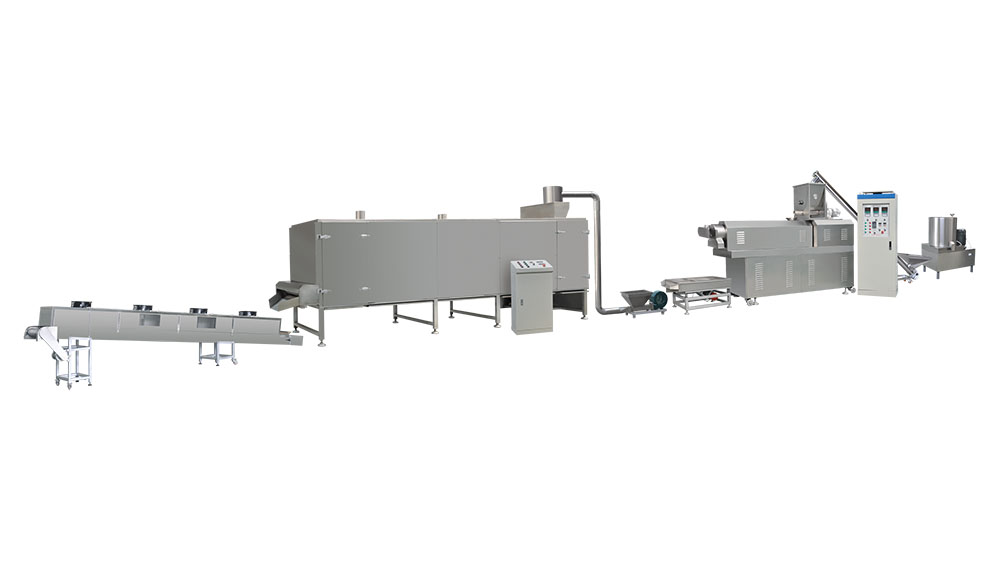

Nutritional rice production line

Production line description:

The nutritious rice production line is a food production equipment developed and produced by Jinan Linao Machinery Equipment Co., Ltd. according to the current food nutrition needs and combined with foreign advanced technology, which is suitable for the production needs of modern enterprises. This production line adapts to the general situation of people in the modern society of intensive food processing, meets people's requirements for balanced nutrition, and avoids the disadvantages of large investment in foreign equipment and high operating costs. At the same time, it has the advantages of high automation and energy saving. The nutritious rice production line can use various grains such as rice, millet, black rice, buckwheat, etc. as raw materials, and add various vitamins, proteins and minerals for processing: extruded, matured, and formed in an extruder to regenerate new grains. Fortified nutritious rice, its eating method is the same as natural rice, and it is simpler, more convenient, nutritious and more adaptable to the modern rhythm of life.

Process composition:

1. Flour mixing machine: separate rice noodles or mix part of additives, add a certain amount of water and mix well.

2. Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Extrusion machine: There is a special control cabinet, which can extrude rice particles under high pressure environment, adjust the process and change the mold to produce rice grains of different shapes.

4. Vibrating screen: The extruded particles contain a little temperature and viscosity, and the particles are spread out through the vibrating screen to avoid sticking together.

5. Air conveyor: convey the product to the oven, and the height of the hoist is determined according to the oven.

6. Multi-layer oven: the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, minus the particle moisture, and increase the shelf life;

7. Cooling conveyor: The dried particles contain a certain temperature, and the packaging quality can be guaranteed by cooling to room temperature.

Hotline:18763911927

Hotline:18763911927

Email:sales@renoextrusion.com

Email:sales@renoextrusion.com