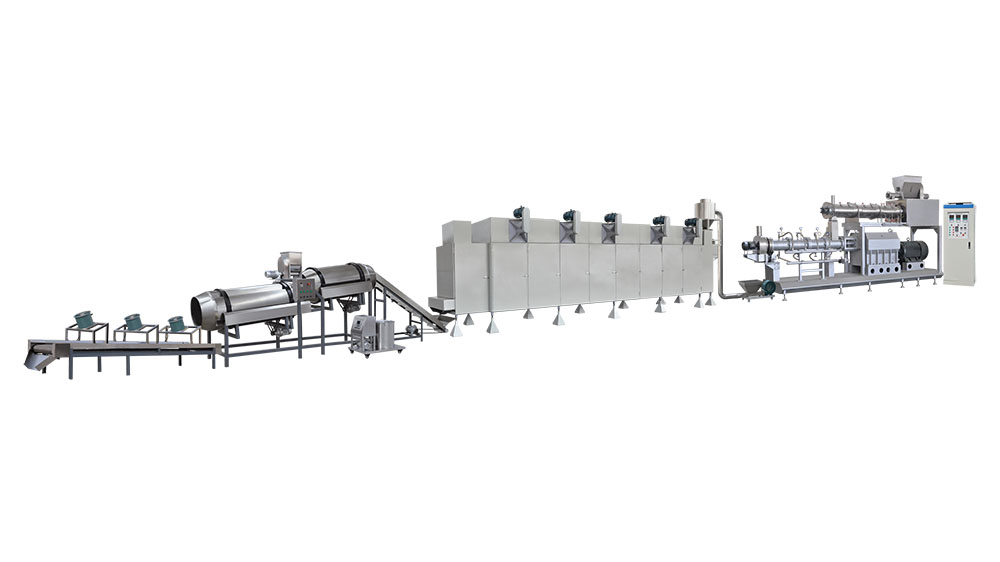

Fish feed production line

Production line description:

This production line can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, soft-shelled turtle, bullfrog and other aquatic feed pellets.

With the development of the aquaculture industry in the direction of scale, intensive, and specialization, its requirements for aquatic feeds are getting higher and higher. Traditional powdered compound feeds, granular compound feeds and other types of compound feeds exist. Poor water stability, fast sedimentation speed, easy to cause feed loss and water quality pollution, etc., has become less and less suitable for the needs of the development of modern aquaculture industry, and the puffed fish feed completely solves these drawbacks, more and more aquaculture farmers And the feed factory installs extruded feed equipment.

Process composition:

1. Mixer: Add a certain proportion of water to the raw materials such as corn flour, rice flour, soybean meal, fish meal, meat meal, cereal flour, additives, etc., and mix well.

2. Feeder: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the twin-screw extruder. This equipment is convenient and quick to load materials, saves labor, and has high efficiency.

3. Twin-screw feed extruder: Under the conditions of high-temperature and high-pressure environment and twin-screw extrusion, the starch structure in the raw materials changes to become easily absorbed nutrients, which are extruded through the feed die and cut through adjustment. The speed of the motor is adjusted until the feed pellets of the same size and length are adjusted. The specific particle size and shape can be obtained by replacing the mold. The feed extruder adopts advanced frequency conversion speed regulation technology, which is more energy-efficient and more precise in speed control. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment.

4. Conveyor: convey the produced feed pellets to the multi-layer drying equipment.

5. Multi-layer oven: The oven is divided into electric oven, oil-fired oven, gas oven and steam oven. The temperature is adjusted by the control cabinet between 0 and 150 degrees. The inside of the oven is stainless steel mesh belt, which is stable in conveying and has low failure rate. The feed pellets pass through a multi-layer S-shaped track cycle to dry the feed pellets to a safe water content, increasing the shelf life.

6. Spraying seasoning line: the oil sprayer sprays oil, attractant, etc. The seasoning tube includes octagonal tube, cylinder, lifting single drum, double drum seasoning line, according to the output and product nature configuration, spraying grease on the surface of the feed, Spray the minced meat and spices at the same time, evenly. This process can also remove the burrs and burrs on the surface of the feed pellets, making the surface of the feed pellets smoother.

7. Cooling conveyor: reduce the surface temperature of the dried feed pellets, promote the solidification of grease, reduce the pellet temperature, and facilitate packaging.

8. Vibrating sieve: sift out the excess external materials and granular slag to ensure the quality while ensuring the reuse of raw materials.

9. Packaging machine: manual sealing machine and automatic packaging machine can be used, please call the manufacturer for details.

Hotline:18763911927

Hotline:18763911927

Email:sales@renoextrusion.com

Email:sales@renoextrusion.com