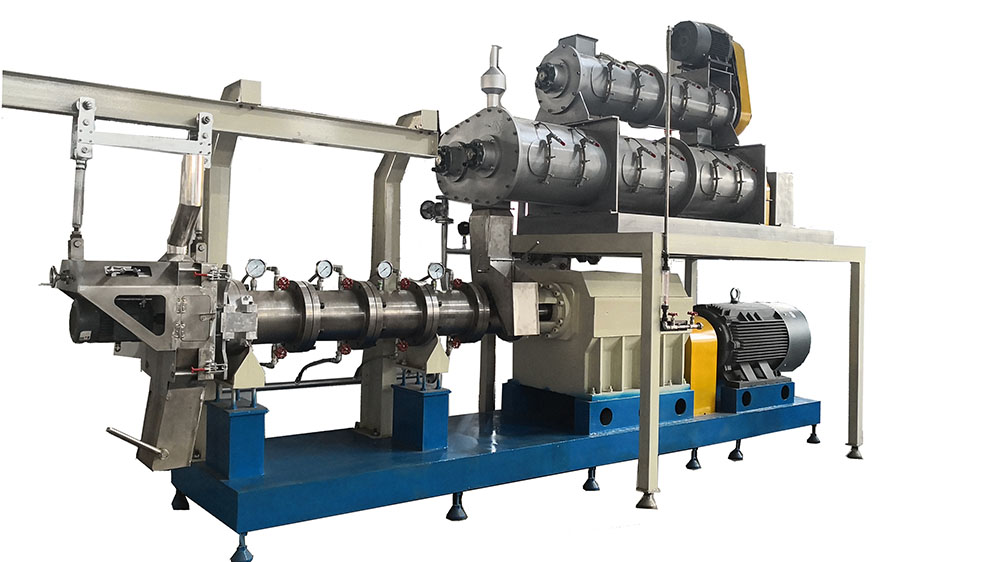

SLG95-II large-scale wet twin-screw extruder:

Equipment introduction:

The twin-screw extruder has a wide range of raw materials, a variety of product shapes, and flexible configuration. Choose different models and configurations to produce different products.

At present, the main applications of twin-screw extruder are:

1. Use corn and potatoes as raw materials to produce all kinds of snack foods;

2. Use flour as raw material to produce various simulated foods;

3. Use vegetable protein as raw material to produce structured protein food (commonly known as artificial meat);

4. It is made of grains, beans or potatoes as raw materials and made into staple food after puffing.

5. Puffed pet food, floating fish feed, etc.

In addition, other products can be produced according to different equipment combinations. Such as: sandwich rice crackers, chocolate bars, bread crumbs, nutritious rice, modified starch, nutritious rice flour, etc.

Mainly speaking, the production of puffed food is the most direct. Puffed food uses grains, beans, potatoes, vegetables, etc. as raw materials, and is processed by puffed food machinery and equipment to produce a wide variety of foods with exquisite appearance, rich nutrition, crisp and delicious food. Therefore, a large category of food is uniquely formed. Moreover, the equipment for producing the puffed food has simple structure, easy operation, low equipment investment, and quick return.

Technical characteristics of twin screw extruder:

1. The host adopts advanced frequency converter speed regulation technology, which makes the equipment powerful, running more stable, and more energy-saving.

2. The screw adopts alloy steel nitriding treatment, the life of the screw is longer, and individual equipment adopts a modular structure, which can be combined according to different needs.

3. Forced lubrication system to ensure that the transmission part of the equipment has a longer life

4. Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

5. The screw has a self-cleaning function, no need to disassemble the screw for cleaning when the machine stops

6. Different screws and length-to-diameter ratios can meet different production processes.

Device parameters:

1. Motor power: main motor 90kw, main motor strength (domestic), Siemens (foreign), feeding is 1.5kw, rotary cutting is 2.2kw

2. Heating: The heating is divided into 4 zones, and the heating method is steam heating.

3. Electrical appliances: three frequency conversion speed regulation, Zhongchen frequency converter (domestic), Delta (foreign) Chint electric devices.

4. Lubrication: oil pump motor 0.37kw, with oil tank, forced lubrication.

5. Output: 1000~3000kg/h.

6. Screw: Combined screw, length 2080mm, material is 38CrMoAl.

Hotline:18763911927

Hotline:18763911927

Email:sales@renoextrusion.com

Email:sales@renoextrusion.com